The market research report for the Thermally Conductive Plastics market includes a prediction for the years up to 2029 as well as in-depth information on the market’s size, rate of growth, revenue, trends, and potential. Also carefully analysed are the main variables affecting the development of this sector. This study involved a thorough quantitative examination of the market, and the findings can be used to inform the creation of growth- and productivity-boosting measures.

Request for free Broacher :https://www.maximizemarketresearch.com/request-sample/60546

Thermally Conductive Plastics Market Overview:

Focusing on the most recent drivers, restraints, and opportunities for the Thermally Conductive Plastics industry, the in-depth company firm’s study is on the Thermally Conductive Plastics market. Discussions with eminent businesses follow to confirm the results. In the secondary review and analysis of the same, both paid and unpaid data sources are utilised. Data on each player’s supply and consumption are assembled using official government sources, independent data sources, and, in the case of publicly traded firms, financial reports of the company. Even if financial documents from businesses are not made available to the general public, the tax division of the local government may be able to obtain them.

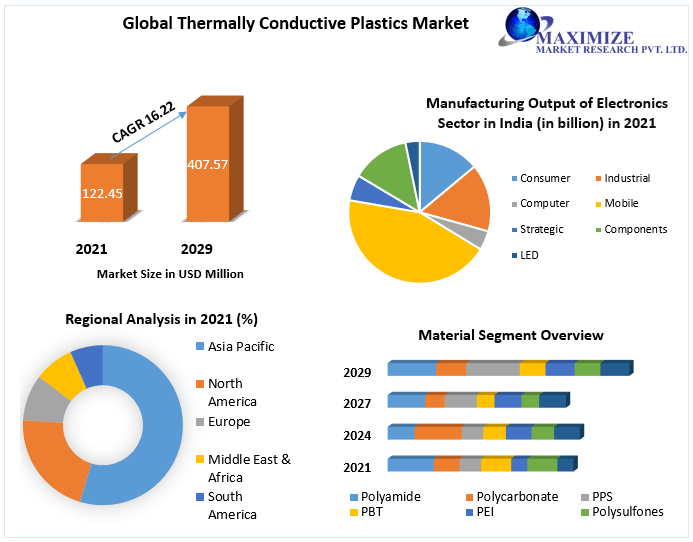

Thermally Conductive Plastics Market was valued at USD 122.45 Million in 2021, and it is expected to reach USD 407.57 Million by 2029, exhibiting a CAGR of 16.22% during the forecast period (2022-2029)

COVID-19 Impact:

The analysis examines the existing and potential impacts of the COVID-19 pandemic on the entire market and delivers more accurate and true estimates in accordance with the market scenario. The world is in anguish due to the coronavirus outbreak. Almost every country has had strict social segregation laws in place, like lockdowns. This has caused disruptions in supply systems. The epidemic has altered societal structures all across the world. The market as a whole is affected by the COVID-19, and as that impact increases in 2019 and 2020, so does the rate of growth. In order to provide decision-makers with reliable data and experiences, businesses and organisations are being compelled by the COVID-19 tragedy to manage risk and digitise operations. This is consistent with the most recent analysis, research, and recommendations from MMR on the management challenges that are crucial for businesses and organisations and have a substantial market impact.

Request for Free sample Pages :https://www.maximizemarketresearch.com/request-sample/60546

Thermally Conductive Plastics Market Key players:

• RTP Company (US)

• Covestro AG (Germany)

• Ensinger Gmbh (Germany)

• HELLA GmbH & Co. KGaA (Germany)

• Lanxess AG (Germany)

• Brenntag AG (Germany)

• Otsuka Chemical (Japan)

• Kaneka Corporation (Japan)

• Mitsubishi Engineering-Plastics Corp. (Japan)

• Toray Industries, Inc. (Japan)

• Kenner Material & System Co. Ltd (Taiwan)

• Nytex Composite Co., Ltd (Taiwan)

• Lotte Advanced Materials Co., Ltd (South Korea)

• LG Chem (South Korea)

• Royal DSM N.V. (Netherlands)

• SABIC- (Saudi Arabia)

• Ugent Tech Sdn Bhd. (Malaysia)

Key company and market share insights:

The major competitors are listed here for audiences to learn about. The main strategic actions these businesses take to maintain market dominance are reviewed in this study, including product portfolio strengthening, M&A, partnerships, new, innovative products, and geographic penetration. In addition to critical financial information and current events, the report also provides the company’s goals. The companies’ global sales, earnings, and profit margins from 2017 through 2022 are also covered in more detail for users.

Thermally Conductive Plastics Market Dynamics:

An Increase in Demand from the Automotive Industry to Increase Demand for the Thermally Conductive Plastics

In 2020, the new registration of motor vehicles reached up to 16,763 units in Europe, 37,467 units in Asia, 3080 units in South America, 17,421 units in North America, 12,733 units in Western Europe, and 5180 units in other regions worldwide. Likewise, a recent study published by the International Netherlands Group (ING) states that the demand for the production and development of electric vehicles has been increasing since the pandemic. It states that the global sales of new electric vehicles have increased by 50% in 2021, and is expected to increase by 8% in 2022. It further states that the sales of electric vehicles have increased by 14% in Europe, 9% in China, and 4% in the US. As a result, increased vehicle demand and manufacturing will raise demand for conductive polymers used in the manufacture of LED lighting, heat removal devices, batteries, and other electrical applications. This is most expected to fuel market growth in the next years.

Fluctuating Crude Oil Prices to Impact Prices of Polymer Resin

Crude oil price volatility due to geopolitical uncertainty, production and storage costs, and high energy costs all have an influence on polymer resin pricing. The raw ingredients for thermally conductive plastics are polymers generated from petroleum fuels, which are subject to commodity price volatility. Oil prices remain unpredictable in the face of the COVID-19 outbreak and Europe’s uncertain geopolitical environment. As a result, changes in crude oil prices have an influence on the pricing of polymer resins and thermally conductive polymers.

Lower Thermal Conductivity than Traditional Metals

Plastics with thermal conductivity are less thermally conductive than metals such as aluminium. To improve heat conductivity, certain polymers are treated with thermally conductive fillers and additives. Metals have problems such as corrosion and heat concentration, which leads to the formation of hot spots on the surface, which may be addressed by thermally conductive polymers. Thermally conductive polymers are design-dependent and compatible with a wide range of polymer resins, allowing for complex structures to be manufactured in a variety of patterns, shapes, and sizes. However, the poorer heat conductivity of these polymers than conventional materials limits market growth.

Thermally Conductive Plastics Market Segment:

The electrical & electronics industry held the largest Conductive Plastics Market share in 2021 and is estimated to grow at a CAGR of 13.7% during the forecast period, thanks to the worldwide increasing demand for conductive plastics during the production of electronic gadgets. The GDP growth rate of consumer electronics, which includes electronic appliances and gadgets such as televisions, computers, laptops, smartphones, tablets, and refrigerators, is expected to reach 8.1%, 5.7%, 1.4%, and 1.7% by the end of 2022 in countries such as India, China, the United States, and Europe, respectively. The global consumer electronics business had a total sales rise of USD 42.8 billion during the first quarter of 2021, a gain of 18% over the same period in 2020, in September 2021. This is expected to increase demand for conductive plastics used in the production of electronic components such as displays, solar cells, batteries, OLED, printing electronic circuits, actuators, and other electronic components, resulting in further growth of the Thermally Conductive Plastics industry during the forecast period.

The automotive industry is being pushed by the development of hybrid electric vehicles (HEV) and electric vehicles (EV), which is expected to increase demand for thermally conductive polymers in automotive electronics. The substitution of mechanical components with thermally conductive designed plastics for automotive LED lighting systems is growing demand for thermally conductive polymers due to the design freedom of 3D components, weight reduction, and heat sinks. The automobile sector is the world’s largest consumer of thermally conductive polymers. PC and PBT are widely utilised in this sector because they have strong strength and thermal resistance features, allowing them to be used in a variety of components such as engine mounts, vehicle batteries top covers, and so on. Plastic materials are increasingly being used instead of metal by automotive engineers due to their low density, which decreases vehicle weight without compromising strength. This enables manufacturers to create smaller battery packs with lighter frames while yet providing great performance in difficult environments like as slick roads and off-road driving, where metal parts may not always perform well.

Regional Analysis:

- North America

- Europe

- Asia-Pacific

- South America

- Middle East and Africa

Speak with our research analyst:https://www.maximizemarketresearch.com/request-sample/60546

About Us:

The Maximize Market Research team does B2B and B2C research on 12,500 high-growth technologies that present potential for organisations in the healthcare, pharmaceuticals, electronics, communications, internet of things, food and beverage, aerospace, defence, and other manufacturing sectors.

Contact us:

MAXIMIZE MARKET RESEARCH PVT. LTD.

3rd Floor, Navale IT Park Phase 2,

Pune Banglore Highway,

Narhe, Pune, Maharashtra 411041, India.

Get More Similar Link :